Factory supplied Lost Wax Casting Kit - EN877 Gray Cast Iron Fittings – Jipeng

Factory supplied Lost Wax Casting Kit - EN877 Gray Cast Iron Fittings – Jipeng Detail:

Overview

Quick Details

| Place of Origin: China | Standard: BS EN877/DIN 19522/ISO 6594 | |||||||

| Application: Water drainage | Color: Red | |||||||

| Coating: Epoxy Resin Paints&Powder epoxy Coating | Marking:OEM or M-Tub or at customers’ requirements | |||||||

| Material: Gray cast Iron | Size: DN40 to DN300 | |||||||

Packaging & Port

Packaging Details: Wooden pallet

Port: Tianjin

Type

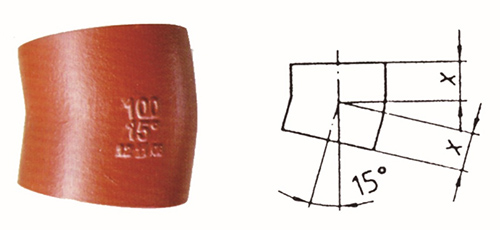

15°short bend

| Nominal size DN/mm | X/mm | |

| 50 | 40 | |

| 70 | 45 | |

| 75 | 50 | |

| 100 | 50 | |

| 125 | 60 | |

| 150 | 65 | |

| 200 | 80 | |

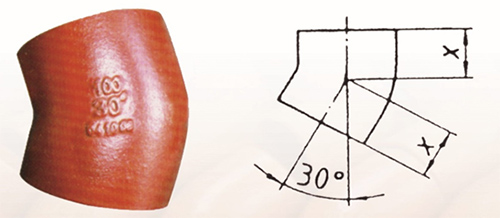

30°short bend

| Nominal size DN/mm | X/mm | |

| 50 | 45 | |

| 70 | 50 | |

| 75 | 60 | |

| 100 | 60 | |

| 125 | 70 | |

| 150 | 80 | |

| 200 | 95 | |

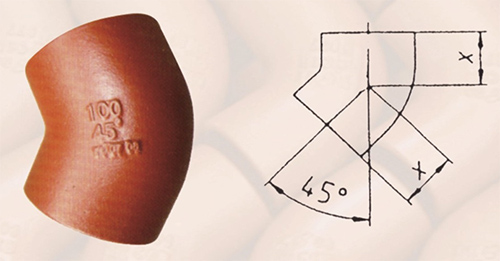

45°short bend

| Nominal size DN/mm | X/mm | |

| 40 | 50 | |

| 50 | 50 | |

| 70 | 60 | |

| 75 | 60 | |

| 100 | 70 | |

| 125 | 80 | |

| 150 | 90 | |

| 200 | 110 | |

| 250 | 130 | |

| 300 | 155 | |

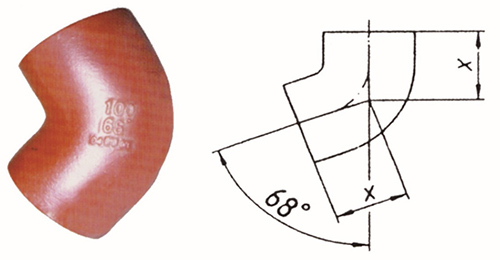

68°short bend

| Nominal size DN | X | |

| 50 | 65 | |

| 70 | 75 | |

| 75 | 80 | |

| 100 | 90 | |

| 125 | 105 | |

| 150 | 120 | |

| 200 | 145 | |

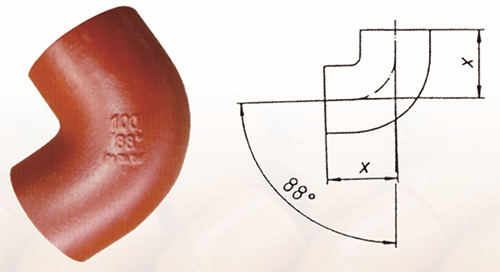

88°short bend

| Nominal size DN/mm | X/mm | |

| 40 | 70 | |

| 50 | 75 | |

| 70 | 90 | |

| 75 | 95 | |

| 100 | 110 | |

| 125 | 125 | |

| 150 | 145 | |

| 200 | 180 | |

| 250 | 220 | |

| 300 | 260 | |

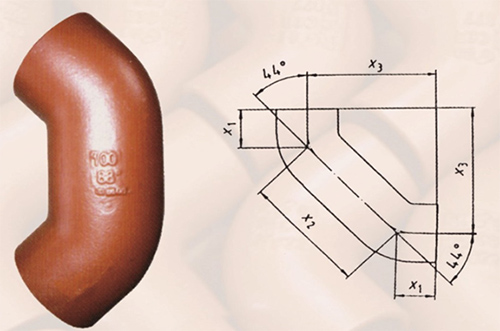

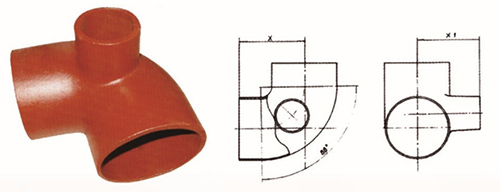

88°double bend

| Nominal size DN | X1 | X2 | X3 | |

| 50 | 50 | 100 | 121 | |

| 70 | 60 | 120 | 145 | |

| 75 | 60 | 120 | 145 | |

| 100 | 70 | 140 | 170 | |

| 125 | 80 | 160 | 195 | |

| 150 | 90 | 180 | 219 | |

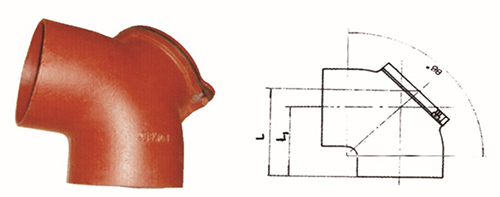

88°short bend with access door

| Nominal size DN | L | L1 | |

| 75 | 113 | 95 | |

| 100 | 137 | 112 | |

| 150 | 184 | 148 | |

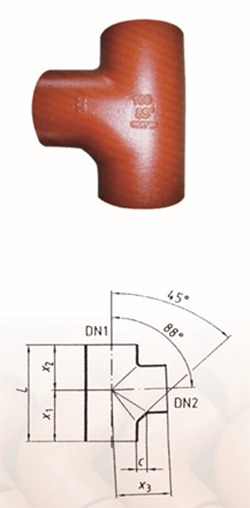

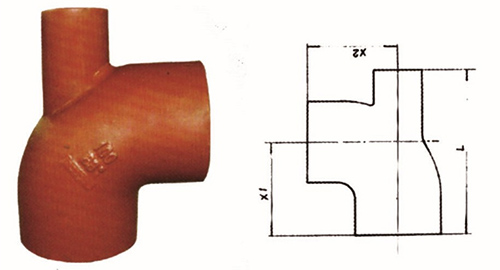

45°single branch

| Nominal size DN1 DN2 | L | X1 | X2 | X3 | |

| 40 | 40 | 160 | 45 | 115 | 115 |

| 50 | 40 | 160 | 45 | 115 | 115 |

| 50 | 50 | 185 | 50 | 135 | 135 |

| 70 | 50 | 190 | 40 | 150 | 150 |

| 70 | 70 | 215 | 55 | 160 | 160 |

| 75 | 50 | 190 | 50 | 140 | 140 |

| 75 | 75 | 225 | 65 | 160 | 160 |

| 100 | 50 | 200 | 35 | 165 | 165 |

| 100 | 70 | 235 | 50 | 185 | 185 |

| 100 | 75 | 230 | 55 | 175 | 175 |

| 100 | 100 | 275 | 70 | 205 | 205 |

| 125 | 50 | 205 | 20 | 185 | 185 |

| 125 | 70 | 240 | 40 | 200 | 200 |

| 125 | 75 | 250 | 50 | 200 | 200 |

| 125 | 100 | 280 | 60 | 220 | 220 |

| 125 | 125 | 320 | 80 | 240 | 240 |

| 150 | 70 | 245 | 30 | 215 | 215 |

| 150 | 75 | 255 | 40 | 215 | 215 |

| 150 | 100 | 295 | 55 | 240 | 240 |

| 150 | 125 | 325 | 70 | 255 | 255 |

| 150 | 150 | 355 | 90 | 265 | 265 |

| 200 | 70 | 255 | 15 | 240 | 240 |

| 200 | 100 | 305 | 40 | 265 | 265 |

| 200 | 125 | 335 | 55 | 280 | 280 |

| 200 | 150 | 375 | 75 | 300 | 300 |

| 200 | 200 | 455 | 115 | 340 | 340 |

| 250 | 150 | 405 | 55 | 350 | 350 |

| 300 | 100 | 350 | 5 | 345 | 345 |

| 300 | 150 | 415 | 35 | 380 | 380 |

| 300 | 200 | 435 | 70 | 415 | 440 |

88°single branch

| Nominal size DN1 DN2 | L | C | X1 | X2 | X3 | |

| 50 | 50 | 145 | 20 | 79 | 66 | 80 |

| 70 | 50 | 155 | 21 | 83 | 72 | 90 |

| 70 | 70 | 180 | 21 | 97 | 83 | 95 |

| 75 | 50 | 180 | 22 | 95 | 85 | 90 |

| 75 | 75 | 180 | 22 | 95 | 85 | 95 |

| 100 | 50 | 170 | 22 | 94 | 76 | 105 |

| 100 | 70 | 190 | 22 | 102 | 88 | 110 |

| 100 | 75 | 190 | 21 | 105 | 85 | 110 |

| 100 | 100 | 220 | 22 | 115 | 105 | 120 |

| 125 | 50 | 180 | 25 | 98 | 82 | 120 |

| 125 | 70 | 200 | 25 | 107 | 93 | 125 |

| 125 | 75 | 205 | 25 | 110 | 95 | 125 |

| 125 | 100 | 235 | 25 | 125 | 110 | 130 |

| 125 | 125 | 260 | 25 | 137 | 123 | 135 |

| 150 | 50 | 200 | 27.5 | 100 | 100 | 140 |

| 150 | 70 | 215 | 27.5 | 115 | 100 | 140 |

| 150 | 100 | 245 | 27.5 | 130 | 115 | 145 |

| 150 | 125 | 275 | 27.5 | 147 | 128 | 150 |

| 150 | 150 | 300 | 27.5 | 158 | 142 | 155 |

| 200 | 150 | 325 | 32.5 | 173 | 152 | 185 |

| 200 | 200 | 379 | 35 | 196 | 181 | 202 |

| 250 | 150 | 364 | 32 | 191 | 171 | 228 |

| 250 | 250 | 470 | 38 | 244 | 226 | 244 |

| 300 | 100 | 348 | 30 | 184 | 164 | 252 |

| 300 | 150 | 404 | 33 | 212 | 192 | 258 |

| 300 | 200 | 455 | 35 | 235 | 220 | 265 |

| 300 | 250 | 526 | 36 | 273 | 253 | 271 |

| 300 | 300 | 548 | 44 | 283 | 265 | 283 |

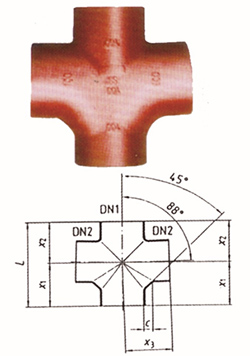

88°double branch

| Nominal size DN1 DN2 | L | C | X1 | X2 | X3 | |

| 100 | 50 | 180 | 22 | 100 | 80 | 105 |

| 100 | 70 | 190 | 22 | 102 | 88 | 110 |

| 100 | 100 | 230 | 22 | 120 | 110 | 120 |

| 125 | 100 | 245 | 25 | 130 | 115 | 135 |

| 150 | 100 | 245 | 27.5 | 130 | 115 | 145 |

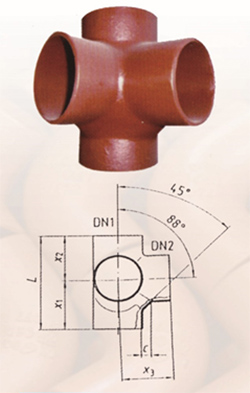

45°corner double branch

| Nominal size DN1 DN2 | L | C | X1 | X2 | X3 | |

| 75 | 50 | 180 | 22 | 100 | 80 | 105 |

| 100 | 70 | 190 | 22 | 102 | 88 | 110 |

| 100 | 100 | 230 | 22 | 120 | 110 | 120 |

| 100 | 100 | 245 | 25 | 130 | 115 | 135 |

| 125 | 100 | 245 | 27.5 | 130 | 115 | 145 |

| 125 | 101 | 246 | 28.5 | 131 | 116 | 146 |

| 125 | 102 | 247 | 29.5 | 132 | 117 | 147 |

| 150 | 103 | 248 | 30.5 | 133 | 118 | 148 |

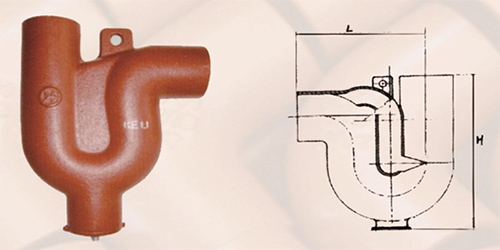

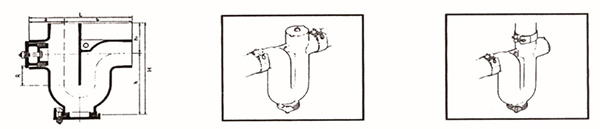

Anti-Siphonic Trap A

| Nominal size DN | L | H | |

| 50 | 148 | 165 | |

| 75 | 196 | 290 | |

| 100 | 272 | 397 | |

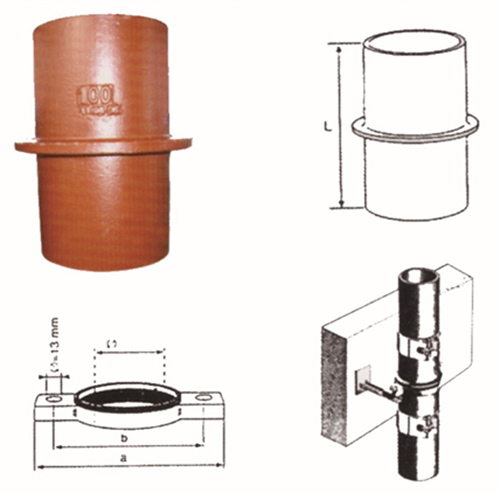

Trap

| Nominal size DN | L | a | b | φ | |

| 50 | 200 | 193 | 148 | 92 | |

| 70 | 200 | 214 | 166 | 114.5 | |

| 75 | 200 | 214 | 166 | 120 | |

| 100 | 200 | 250 | 202 | 148 | |

| 125 | 200 | 275 | 225.5 | 174 | |

| 150 | 200 | 301 | 253.5 | 200 | |

| 200 | 200 | 360 | 310.5 | 253 | |

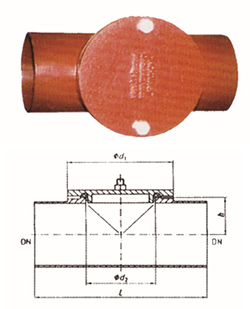

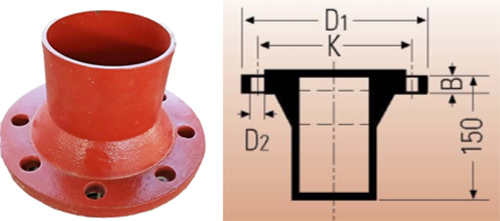

Reducer

| Nominal Size DN | D1 | D2 | B | K* | |

| 100 | 220 | 18 | 24 | 180 | |

| 150 | 285 | 22 | 26 | 240 | |

| 200 | 340 | 22 | 26 | 295 | |

Short pipe with access oval door

| Nominal size DN | d2 | d1 | H | L | |

| 50 | 53 | 105 | 35 | 190 | |

| 70 | 73 | 125 | 45 | 210 | |

| 75 | 78 | 135 | 90 | 220 | |

| 100 | 104 | 159 | 61 | 260 | |

Short pipe with rectangular door

| Nominal size DN | A | F | G | h | L | |

| 100 | 200 | 230 | 157 | 60 | 340 | |

| 125 | 225 | 255 | 190 | 73 | 370 | |

| 150 | 250 | 280 | 215 | 85 | 395 | |

| 200 | 300 | 330 | 265 | 110 | 465 | |

| 300 | 400 | 476 | 380 | 168 | 640 | |

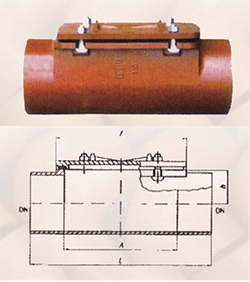

Down pipe supports

| Nominal size DN | A | F | G | h | L | |

| 100 | 200 | 230 | 157 | 60 | 340 | |

| 125 | 225 | 255 | 190 | 73 | 370 | |

| 150 | 250 | 280 | 215 | 85 | 395 | |

| 200 | 300 | 330 | 265 | 110 | 465 | |

| 300 | 400 | 476 | 380 | 168 | 640 | |

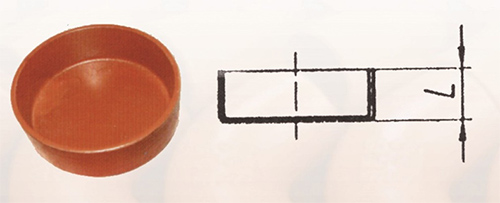

Gap/plug

| Nominal size DN | L | |

| 50 | 30 | |

| 70 | 35 | |

| 75 | 35 | |

| 100 | 40 | |

| 125 | 45 | |

| 150 | 50 | |

| 200 | 60 | |

| 250 | 70 | |

| 300 | 80 | |

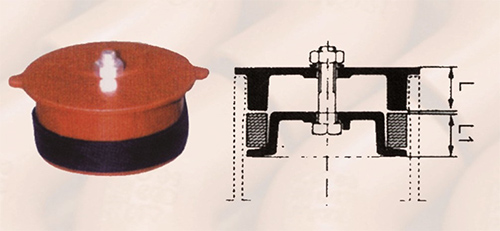

Expansion plug

| Nominal size DN | L | L1 | |

| 50 | 20 | 20 | |

| 70 | 28 | 27 | |

| 75 | 28 | 27 | |

| 100 | 28 | 27 | |

| 125 | 28 | 27 | |

| 150 | 28 | 27 | |

| 200 | 29 | 30 | |

88°short bend with heel opening

| Nominal size DN | X1 | X2 | L | |

| 100 | 50 | 112 | 115 | 202 |

| 100 | 50 | 110 | 110 | 215 |

88°short bend with vent

| Nominal size DN | X | X1 | |

| 100 | 50 | 110 | 95 |

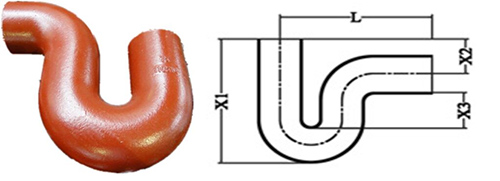

P trap

| Nominal Size DN | L | X1 | X2 | X3 | |

| 50 | 180 | 200 | 60 | 75 | |

| 75 | 180 | 200 | 60 | 75 | |

| 100 | 310 | 300 | 110 | 75 | |

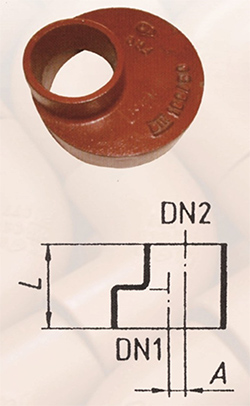

Flange adapter

| Nominal Size DN | L | X1 | X2 | X3 | |

| 50 | 180 | 200 | 60 | 75 | |

| 75 | 180 | 200 | 60 | 75 | |

| 100 | 310 | 300 | 110 | 75 | |

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Factory supplied Lost Wax Casting Kit - EN877 Gray Cast Iron Fittings – Jipeng, The product will supply to all over the world, such as: Peru, Nepal, Guinea, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.