China OEM En877 Cast Iron Fittings Factory Quotes – EN877 Gray Cast Iron Fittings – Jipeng

China OEM En877 Cast Iron Fittings Factory Quotes – EN877 Gray Cast Iron Fittings – Jipeng Detail:

Overview

Quick Details

| Place of Origin: China | Standard: BS EN877/DIN 19522/ISO 6594 | |||||||

| Application: Water drainage | Color: Red | |||||||

| Coating: Epoxy Resin Paints&Powder epoxy Coating | Marking:OEM or M-Tub or at customers’ requirements | |||||||

| Material: Gray cast Iron | Size: DN40 to DN300 | |||||||

Packaging & Port

Packaging Details: Wooden pallet

Port: Tianjin

Type

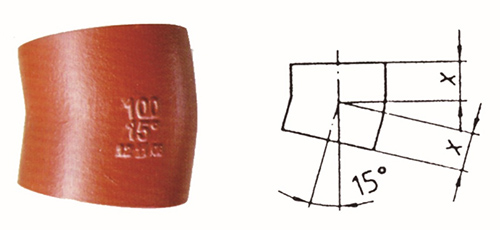

15°short bend

| Nominal size DN/mm | X/mm | |

| 50 | 40 | |

| 70 | 45 | |

| 75 | 50 | |

| 100 | 50 | |

| 125 | 60 | |

| 150 | 65 | |

| 200 | 80 | |

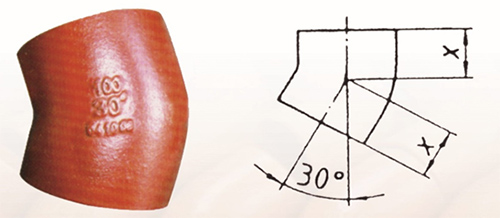

30°short bend

| Nominal size DN/mm | X/mm | |

| 50 | 45 | |

| 70 | 50 | |

| 75 | 60 | |

| 100 | 60 | |

| 125 | 70 | |

| 150 | 80 | |

| 200 | 95 | |

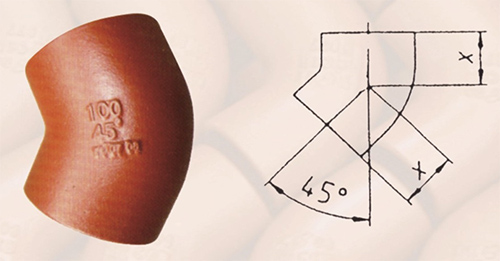

45°short bend

| Nominal size DN/mm | X/mm | |

| 40 | 50 | |

| 50 | 50 | |

| 70 | 60 | |

| 75 | 60 | |

| 100 | 70 | |

| 125 | 80 | |

| 150 | 90 | |

| 200 | 110 | |

| 250 | 130 | |

| 300 | 155 | |

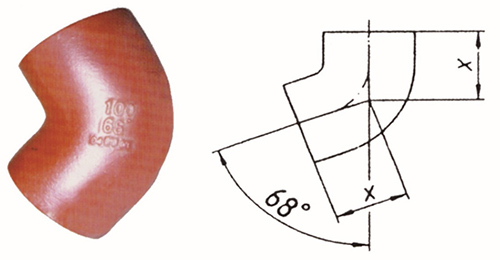

68°short bend

| Nominal size DN | X | |

| 50 | 65 | |

| 70 | 75 | |

| 75 | 80 | |

| 100 | 90 | |

| 125 | 105 | |

| 150 | 120 | |

| 200 | 145 | |

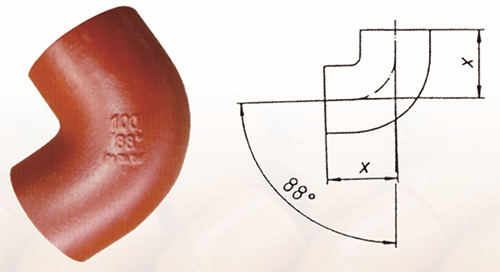

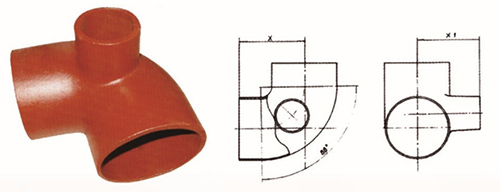

88°short bend

| Nominal size DN/mm | X/mm | |

| 40 | 70 | |

| 50 | 75 | |

| 70 | 90 | |

| 75 | 95 | |

| 100 | 110 | |

| 125 | 125 | |

| 150 | 145 | |

| 200 | 180 | |

| 250 | 220 | |

| 300 | 260 | |

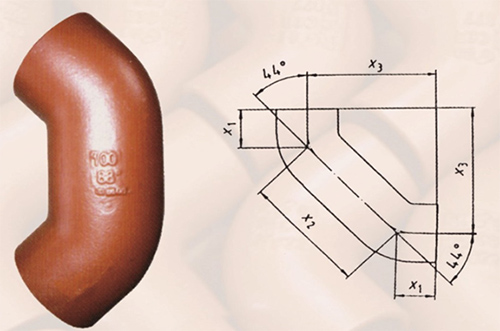

88°double bend

| Nominal size DN | X1 | X2 | X3 | |

| 50 | 50 | 100 | 121 | |

| 70 | 60 | 120 | 145 | |

| 75 | 60 | 120 | 145 | |

| 100 | 70 | 140 | 170 | |

| 125 | 80 | 160 | 195 | |

| 150 | 90 | 180 | 219 | |

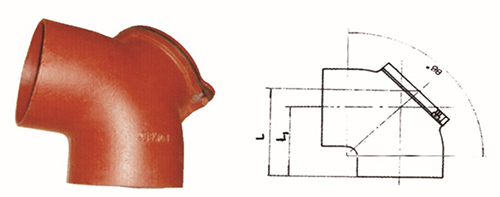

88°short bend with access door

| Nominal size DN | L | L1 | |

| 75 | 113 | 95 | |

| 100 | 137 | 112 | |

| 150 | 184 | 148 | |

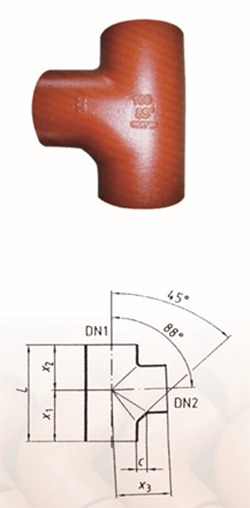

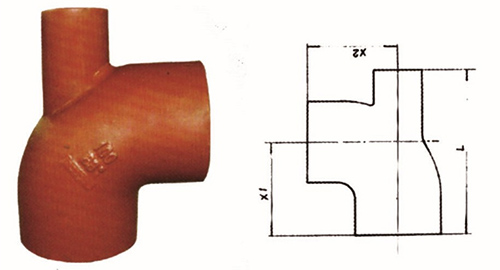

45°single branch

| Nominal size DN1 DN2 | L | X1 | X2 | X3 | |

| 40 | 40 | 160 | 45 | 115 | 115 |

| 50 | 40 | 160 | 45 | 115 | 115 |

| 50 | 50 | 185 | 50 | 135 | 135 |

| 70 | 50 | 190 | 40 | 150 | 150 |

| 70 | 70 | 215 | 55 | 160 | 160 |

| 75 | 50 | 190 | 50 | 140 | 140 |

| 75 | 75 | 225 | 65 | 160 | 160 |

| 100 | 50 | 200 | 35 | 165 | 165 |

| 100 | 70 | 235 | 50 | 185 | 185 |

| 100 | 75 | 230 | 55 | 175 | 175 |

| 100 | 100 | 275 | 70 | 205 | 205 |

| 125 | 50 | 205 | 20 | 185 | 185 |

| 125 | 70 | 240 | 40 | 200 | 200 |

| 125 | 75 | 250 | 50 | 200 | 200 |

| 125 | 100 | 280 | 60 | 220 | 220 |

| 125 | 125 | 320 | 80 | 240 | 240 |

| 150 | 70 | 245 | 30 | 215 | 215 |

| 150 | 75 | 255 | 40 | 215 | 215 |

| 150 | 100 | 295 | 55 | 240 | 240 |

| 150 | 125 | 325 | 70 | 255 | 255 |

| 150 | 150 | 355 | 90 | 265 | 265 |

| 200 | 70 | 255 | 15 | 240 | 240 |

| 200 | 100 | 305 | 40 | 265 | 265 |

| 200 | 125 | 335 | 55 | 280 | 280 |

| 200 | 150 | 375 | 75 | 300 | 300 |

| 200 | 200 | 455 | 115 | 340 | 340 |

| 250 | 150 | 405 | 55 | 350 | 350 |

| 300 | 100 | 350 | 5 | 345 | 345 |

| 300 | 150 | 415 | 35 | 380 | 380 |

| 300 | 200 | 435 | 70 | 415 | 440 |

88°single branch

| Nominal size DN1 DN2 | L | C | X1 | X2 | X3 | |

| 50 | 50 | 145 | 20 | 79 | 66 | 80 |

| 70 | 50 | 155 | 21 | 83 | 72 | 90 |

| 70 | 70 | 180 | 21 | 97 | 83 | 95 |

| 75 | 50 | 180 | 22 | 95 | 85 | 90 |

| 75 | 75 | 180 | 22 | 95 | 85 | 95 |

| 100 | 50 | 170 | 22 | 94 | 76 | 105 |

| 100 | 70 | 190 | 22 | 102 | 88 | 110 |

| 100 | 75 | 190 | 21 | 105 | 85 | 110 |

| 100 | 100 | 220 | 22 | 115 | 105 | 120 |

| 125 | 50 | 180 | 25 | 98 | 82 | 120 |

| 125 | 70 | 200 | 25 | 107 | 93 | 125 |

| 125 | 75 | 205 | 25 | 110 | 95 | 125 |

| 125 | 100 | 235 | 25 | 125 | 110 | 130 |

| 125 | 125 | 260 | 25 | 137 | 123 | 135 |

| 150 | 50 | 200 | 27.5 | 100 | 100 | 140 |

| 150 | 70 | 215 | 27.5 | 115 | 100 | 140 |

| 150 | 100 | 245 | 27.5 | 130 | 115 | 145 |

| 150 | 125 | 275 | 27.5 | 147 | 128 | 150 |

| 150 | 150 | 300 | 27.5 | 158 | 142 | 155 |

| 200 | 150 | 325 | 32.5 | 173 | 152 | 185 |

| 200 | 200 | 379 | 35 | 196 | 181 | 202 |

| 250 | 150 | 364 | 32 | 191 | 171 | 228 |

| 250 | 250 | 470 | 38 | 244 | 226 | 244 |

| 300 | 100 | 348 | 30 | 184 | 164 | 252 |

| 300 | 150 | 404 | 33 | 212 | 192 | 258 |

| 300 | 200 | 455 | 35 | 235 | 220 | 265 |

| 300 | 250 | 526 | 36 | 273 | 253 | 271 |

| 300 | 300 | 548 | 44 | 283 | 265 | 283 |

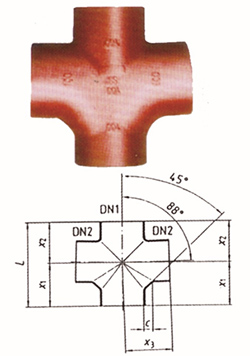

88°double branch

| Nominal size DN1 DN2 | L | C | X1 | X2 | X3 | |

| 100 | 50 | 180 | 22 | 100 | 80 | 105 |

| 100 | 70 | 190 | 22 | 102 | 88 | 110 |

| 100 | 100 | 230 | 22 | 120 | 110 | 120 |

| 125 | 100 | 245 | 25 | 130 | 115 | 135 |

| 150 | 100 | 245 | 27.5 | 130 | 115 | 145 |

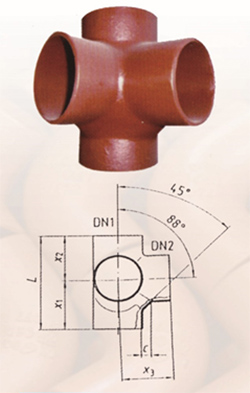

45°corner double branch

| Nominal size DN1 DN2 | L | C | X1 | X2 | X3 | |

| 75 | 50 | 180 | 22 | 100 | 80 | 105 |

| 100 | 70 | 190 | 22 | 102 | 88 | 110 |

| 100 | 100 | 230 | 22 | 120 | 110 | 120 |

| 100 | 100 | 245 | 25 | 130 | 115 | 135 |

| 125 | 100 | 245 | 27.5 | 130 | 115 | 145 |

| 125 | 101 | 246 | 28.5 | 131 | 116 | 146 |

| 125 | 102 | 247 | 29.5 | 132 | 117 | 147 |

| 150 | 103 | 248 | 30.5 | 133 | 118 | 148 |

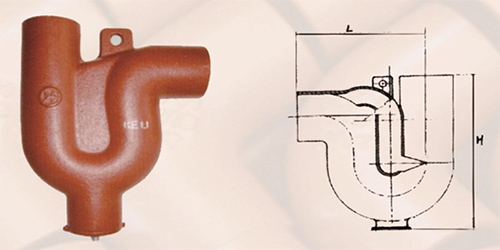

Anti-Siphonic Trap A

| Nominal size DN | L | H | |

| 50 | 148 | 165 | |

| 75 | 196 | 290 | |

| 100 | 272 | 397 | |

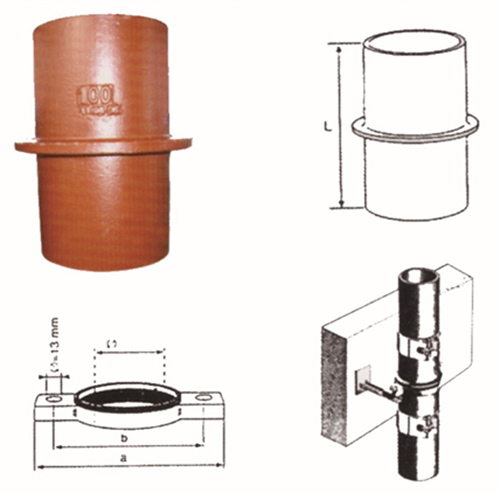

Trap

| Nominal size DN | L | a | b | φ | |

| 50 | 200 | 193 | 148 | 92 | |

| 70 | 200 | 214 | 166 | 114.5 | |

| 75 | 200 | 214 | 166 | 120 | |

| 100 | 200 | 250 | 202 | 148 | |

| 125 | 200 | 275 | 225.5 | 174 | |

| 150 | 200 | 301 | 253.5 | 200 | |

| 200 | 200 | 360 | 310.5 | 253 | |

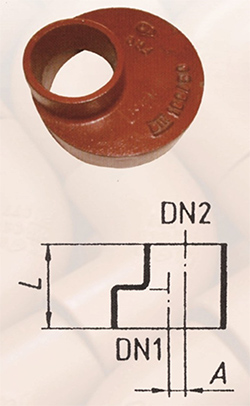

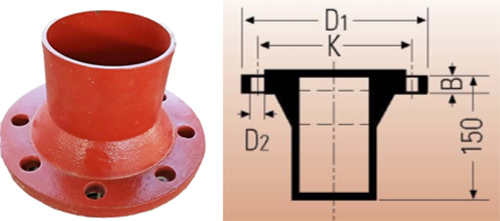

Reducer

| Nominal Size DN | D1 | D2 | B | K* | |

| 100 | 220 | 18 | 24 | 180 | |

| 150 | 285 | 22 | 26 | 240 | |

| 200 | 340 | 22 | 26 | 295 | |

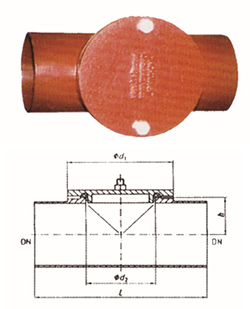

Short pipe with access oval door

| Nominal size DN | d2 | d1 | H | L | |

| 50 | 53 | 105 | 35 | 190 | |

| 70 | 73 | 125 | 45 | 210 | |

| 75 | 78 | 135 | 90 | 220 | |

| 100 | 104 | 159 | 61 | 260 | |

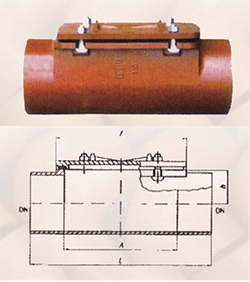

Short pipe with rectangular door

| Nominal size DN | A | F | G | h | L | |

| 100 | 200 | 230 | 157 | 60 | 340 | |

| 125 | 225 | 255 | 190 | 73 | 370 | |

| 150 | 250 | 280 | 215 | 85 | 395 | |

| 200 | 300 | 330 | 265 | 110 | 465 | |

| 300 | 400 | 476 | 380 | 168 | 640 | |

Down pipe supports

| Nominal size DN | A | F | G | h | L | |

| 100 | 200 | 230 | 157 | 60 | 340 | |

| 125 | 225 | 255 | 190 | 73 | 370 | |

| 150 | 250 | 280 | 215 | 85 | 395 | |

| 200 | 300 | 330 | 265 | 110 | 465 | |

| 300 | 400 | 476 | 380 | 168 | 640 | |

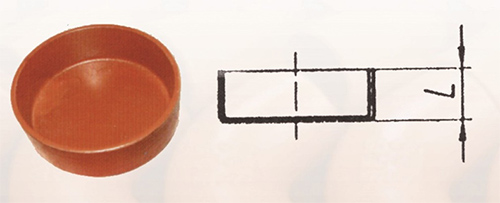

Gap/plug

| Nominal size DN | L | |

| 50 | 30 | |

| 70 | 35 | |

| 75 | 35 | |

| 100 | 40 | |

| 125 | 45 | |

| 150 | 50 | |

| 200 | 60 | |

| 250 | 70 | |

| 300 | 80 | |

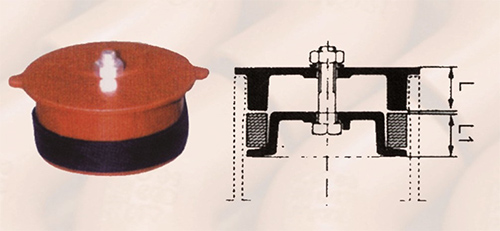

Expansion plug

| Nominal size DN | L | L1 | |

| 50 | 20 | 20 | |

| 70 | 28 | 27 | |

| 75 | 28 | 27 | |

| 100 | 28 | 27 | |

| 125 | 28 | 27 | |

| 150 | 28 | 27 | |

| 200 | 29 | 30 | |

88°short bend with heel opening

| Nominal size DN | X1 | X2 | L | |

| 100 | 50 | 112 | 115 | 202 |

| 100 | 50 | 110 | 110 | 215 |

88°short bend with vent

| Nominal size DN | X | X1 | |

| 100 | 50 | 110 | 95 |

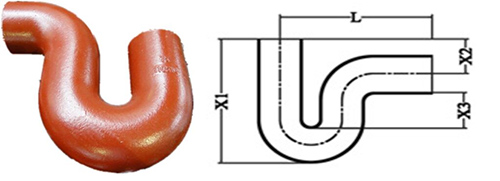

P trap

| Nominal Size DN | L | X1 | X2 | X3 | |

| 50 | 180 | 200 | 60 | 75 | |

| 75 | 180 | 200 | 60 | 75 | |

| 100 | 310 | 300 | 110 | 75 | |

Flange adapter

| Nominal Size DN | L | X1 | X2 | X3 | |

| 50 | 180 | 200 | 60 | 75 | |

| 75 | 180 | 200 | 60 | 75 | |

| 100 | 310 | 300 | 110 | 75 | |

Product detail pictures:

Related Product Guide:

Fast and fantastic quotations, informed advisers to help you choose the correct products that suits all your needs, a short manufacturing time, responsible good quality control and distinct companies for paying and shipping affairs for China OEM En877 Cast Iron Fittings Factory Quotes – EN877 Gray Cast Iron Fittings – Jipeng, The product will supply to all over the world, such as: Finland, Orlando, Italy, we always keep our credit and mutual benefit to our client, insist our high quality service to moving our clients. always welcome the our friends and clients to come and visit our company and guid our business, if you are interested in our products, you can also submit your purchase information online, and we will contact you immediately, we keep our highly sincere cooperation and wish everything in your side are all well.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.