China OEM En877 Cast Iron Fittings Factory Quotes – EN877 Gray Cast Iron Fittings – Jipeng

China OEM En877 Cast Iron Fittings Factory Quotes – EN877 Gray Cast Iron Fittings – Jipeng Detail:

Overview

Quick Details

| Place of Origin: China | Standard: BS EN877/DIN 19522/ISO 6594 | |||||||

| Application: Water drainage | Color: Red | |||||||

| Coating: Epoxy Resin Paints&Powder epoxy Coating | Marking:OEM or M-Tub or at customers’ requirements | |||||||

| Material: Gray cast Iron | Size: DN40 to DN300 | |||||||

Packaging & Port

Packaging Details: Wooden pallet

Port: Tianjin

Type

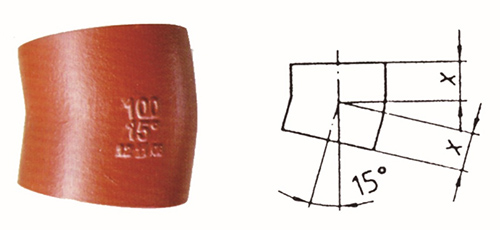

15°short bend

| Nominal size DN/mm | X/mm | |

| 50 | 40 | |

| 70 | 45 | |

| 75 | 50 | |

| 100 | 50 | |

| 125 | 60 | |

| 150 | 65 | |

| 200 | 80 | |

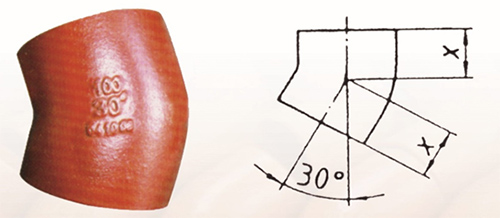

30°short bend

| Nominal size DN/mm | X/mm | |

| 50 | 45 | |

| 70 | 50 | |

| 75 | 60 | |

| 100 | 60 | |

| 125 | 70 | |

| 150 | 80 | |

| 200 | 95 | |

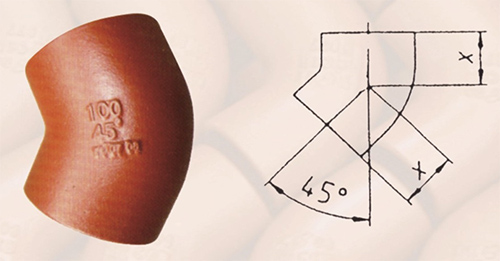

45°short bend

| Nominal size DN/mm | X/mm | |

| 40 | 50 | |

| 50 | 50 | |

| 70 | 60 | |

| 75 | 60 | |

| 100 | 70 | |

| 125 | 80 | |

| 150 | 90 | |

| 200 | 110 | |

| 250 | 130 | |

| 300 | 155 | |

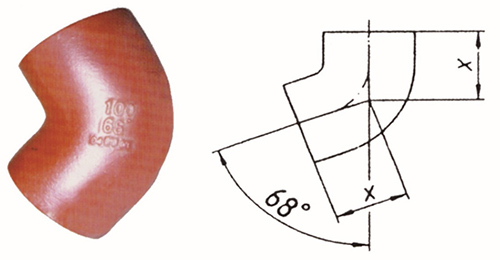

68°short bend

| Nominal size DN | X | |

| 50 | 65 | |

| 70 | 75 | |

| 75 | 80 | |

| 100 | 90 | |

| 125 | 105 | |

| 150 | 120 | |

| 200 | 145 | |

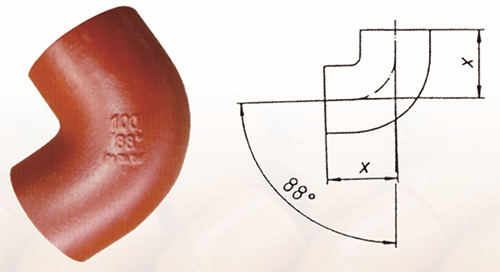

88°short bend

| Nominal size DN/mm | X/mm | |

| 40 | 70 | |

| 50 | 75 | |

| 70 | 90 | |

| 75 | 95 | |

| 100 | 110 | |

| 125 | 125 | |

| 150 | 145 | |

| 200 | 180 | |

| 250 | 220 | |

| 300 | 260 | |

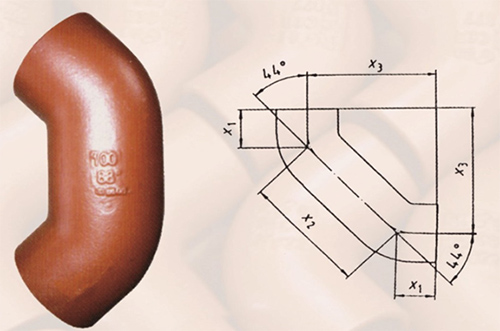

88°double bend

| Nominal size DN | X1 | X2 | X3 | |

| 50 | 50 | 100 | 121 | |

| 70 | 60 | 120 | 145 | |

| 75 | 60 | 120 | 145 | |

| 100 | 70 | 140 | 170 | |

| 125 | 80 | 160 | 195 | |

| 150 | 90 | 180 | 219 | |

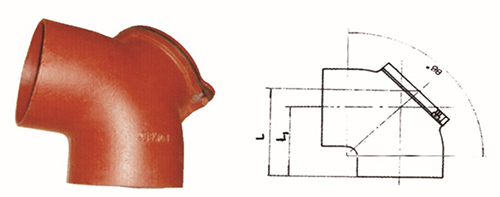

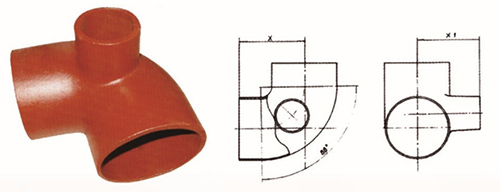

88°short bend with access door

| Nominal size DN | L | L1 | |

| 75 | 113 | 95 | |

| 100 | 137 | 112 | |

| 150 | 184 | 148 | |

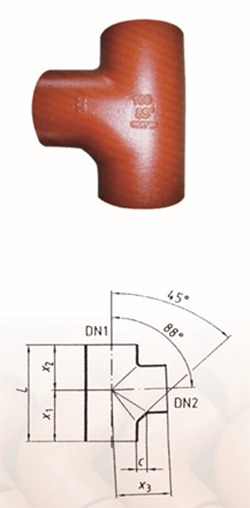

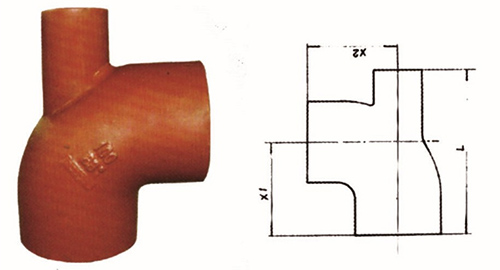

45°single branch

| Nominal size DN1 DN2 | L | X1 | X2 | X3 | |

| 40 | 40 | 160 | 45 | 115 | 115 |

| 50 | 40 | 160 | 45 | 115 | 115 |

| 50 | 50 | 185 | 50 | 135 | 135 |

| 70 | 50 | 190 | 40 | 150 | 150 |

| 70 | 70 | 215 | 55 | 160 | 160 |

| 75 | 50 | 190 | 50 | 140 | 140 |

| 75 | 75 | 225 | 65 | 160 | 160 |

| 100 | 50 | 200 | 35 | 165 | 165 |

| 100 | 70 | 235 | 50 | 185 | 185 |

| 100 | 75 | 230 | 55 | 175 | 175 |

| 100 | 100 | 275 | 70 | 205 | 205 |

| 125 | 50 | 205 | 20 | 185 | 185 |

| 125 | 70 | 240 | 40 | 200 | 200 |

| 125 | 75 | 250 | 50 | 200 | 200 |

| 125 | 100 | 280 | 60 | 220 | 220 |

| 125 | 125 | 320 | 80 | 240 | 240 |

| 150 | 70 | 245 | 30 | 215 | 215 |

| 150 | 75 | 255 | 40 | 215 | 215 |

| 150 | 100 | 295 | 55 | 240 | 240 |

| 150 | 125 | 325 | 70 | 255 | 255 |

| 150 | 150 | 355 | 90 | 265 | 265 |

| 200 | 70 | 255 | 15 | 240 | 240 |

| 200 | 100 | 305 | 40 | 265 | 265 |

| 200 | 125 | 335 | 55 | 280 | 280 |

| 200 | 150 | 375 | 75 | 300 | 300 |

| 200 | 200 | 455 | 115 | 340 | 340 |

| 250 | 150 | 405 | 55 | 350 | 350 |

| 300 | 100 | 350 | 5 | 345 | 345 |

| 300 | 150 | 415 | 35 | 380 | 380 |

| 300 | 200 | 435 | 70 | 415 | 440 |

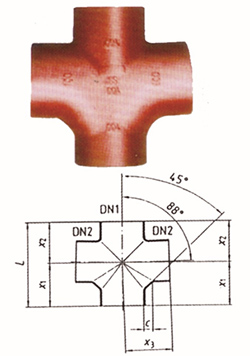

88°single branch

| Nominal size DN1 DN2 | L | C | X1 | X2 | X3 | |

| 50 | 50 | 145 | 20 | 79 | 66 | 80 |

| 70 | 50 | 155 | 21 | 83 | 72 | 90 |

| 70 | 70 | 180 | 21 | 97 | 83 | 95 |

| 75 | 50 | 180 | 22 | 95 | 85 | 90 |

| 75 | 75 | 180 | 22 | 95 | 85 | 95 |

| 100 | 50 | 170 | 22 | 94 | 76 | 105 |

| 100 | 70 | 190 | 22 | 102 | 88 | 110 |

| 100 | 75 | 190 | 21 | 105 | 85 | 110 |

| 100 | 100 | 220 | 22 | 115 | 105 | 120 |

| 125 | 50 | 180 | 25 | 98 | 82 | 120 |

| 125 | 70 | 200 | 25 | 107 | 93 | 125 |

| 125 | 75 | 205 | 25 | 110 | 95 | 125 |

| 125 | 100 | 235 | 25 | 125 | 110 | 130 |

| 125 | 125 | 260 | 25 | 137 | 123 | 135 |

| 150 | 50 | 200 | 27.5 | 100 | 100 | 140 |

| 150 | 70 | 215 | 27.5 | 115 | 100 | 140 |

| 150 | 100 | 245 | 27.5 | 130 | 115 | 145 |

| 150 | 125 | 275 | 27.5 | 147 | 128 | 150 |

| 150 | 150 | 300 | 27.5 | 158 | 142 | 155 |

| 200 | 150 | 325 | 32.5 | 173 | 152 | 185 |

| 200 | 200 | 379 | 35 | 196 | 181 | 202 |

| 250 | 150 | 364 | 32 | 191 | 171 | 228 |

| 250 | 250 | 470 | 38 | 244 | 226 | 244 |

| 300 | 100 | 348 | 30 | 184 | 164 | 252 |

| 300 | 150 | 404 | 33 | 212 | 192 | 258 |

| 300 | 200 | 455 | 35 | 235 | 220 | 265 |

| 300 | 250 | 526 | 36 | 273 | 253 | 271 |

| 300 | 300 | 548 | 44 | 283 | 265 | 283 |

88°double branch

| Nominal size DN1 DN2 | L | C | X1 | X2 | X3 | |

| 100 | 50 | 180 | 22 | 100 | 80 | 105 |

| 100 | 70 | 190 | 22 | 102 | 88 | 110 |

| 100 | 100 | 230 | 22 | 120 | 110 | 120 |

| 125 | 100 | 245 | 25 | 130 | 115 | 135 |

| 150 | 100 | 245 | 27.5 | 130 | 115 | 145 |

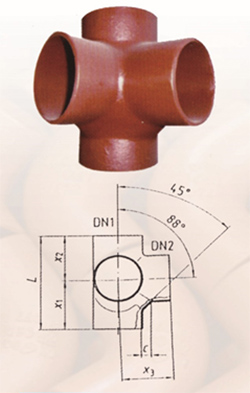

45°corner double branch

| Nominal size DN1 DN2 | L | C | X1 | X2 | X3 | |

| 75 | 50 | 180 | 22 | 100 | 80 | 105 |

| 100 | 70 | 190 | 22 | 102 | 88 | 110 |

| 100 | 100 | 230 | 22 | 120 | 110 | 120 |

| 100 | 100 | 245 | 25 | 130 | 115 | 135 |

| 125 | 100 | 245 | 27.5 | 130 | 115 | 145 |

| 125 | 101 | 246 | 28.5 | 131 | 116 | 146 |

| 125 | 102 | 247 | 29.5 | 132 | 117 | 147 |

| 150 | 103 | 248 | 30.5 | 133 | 118 | 148 |

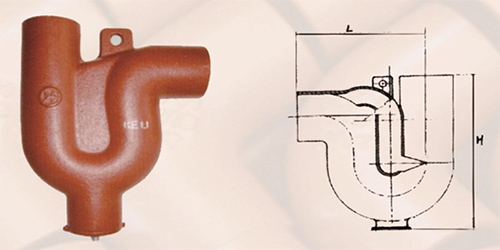

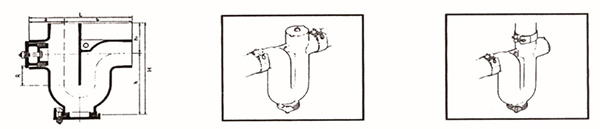

Anti-Siphonic Trap A

| Nominal size DN | L | H | |

| 50 | 148 | 165 | |

| 75 | 196 | 290 | |

| 100 | 272 | 397 | |

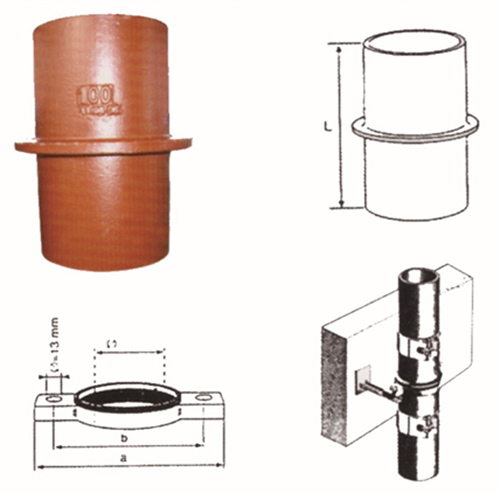

Trap

| Nominal size DN | L | a | b | φ | |

| 50 | 200 | 193 | 148 | 92 | |

| 70 | 200 | 214 | 166 | 114.5 | |

| 75 | 200 | 214 | 166 | 120 | |

| 100 | 200 | 250 | 202 | 148 | |

| 125 | 200 | 275 | 225.5 | 174 | |

| 150 | 200 | 301 | 253.5 | 200 | |

| 200 | 200 | 360 | 310.5 | 253 | |

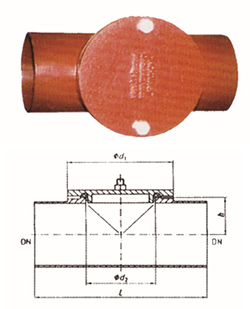

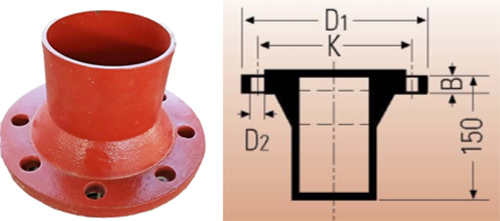

Reducer

| Nominal Size DN | D1 | D2 | B | K* | |

| 100 | 220 | 18 | 24 | 180 | |

| 150 | 285 | 22 | 26 | 240 | |

| 200 | 340 | 22 | 26 | 295 | |

Short pipe with access oval door

| Nominal size DN | d2 | d1 | H | L | |

| 50 | 53 | 105 | 35 | 190 | |

| 70 | 73 | 125 | 45 | 210 | |

| 75 | 78 | 135 | 90 | 220 | |

| 100 | 104 | 159 | 61 | 260 | |

Short pipe with rectangular door

| Nominal size DN | A | F | G | h | L | |

| 100 | 200 | 230 | 157 | 60 | 340 | |

| 125 | 225 | 255 | 190 | 73 | 370 | |

| 150 | 250 | 280 | 215 | 85 | 395 | |

| 200 | 300 | 330 | 265 | 110 | 465 | |

| 300 | 400 | 476 | 380 | 168 | 640 | |

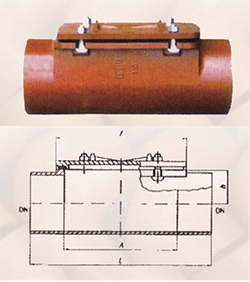

Down pipe supports

| Nominal size DN | A | F | G | h | L | |

| 100 | 200 | 230 | 157 | 60 | 340 | |

| 125 | 225 | 255 | 190 | 73 | 370 | |

| 150 | 250 | 280 | 215 | 85 | 395 | |

| 200 | 300 | 330 | 265 | 110 | 465 | |

| 300 | 400 | 476 | 380 | 168 | 640 | |

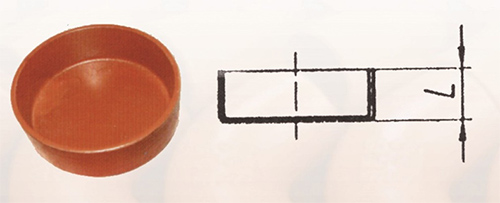

Gap/plug

| Nominal size DN | L | |

| 50 | 30 | |

| 70 | 35 | |

| 75 | 35 | |

| 100 | 40 | |

| 125 | 45 | |

| 150 | 50 | |

| 200 | 60 | |

| 250 | 70 | |

| 300 | 80 | |

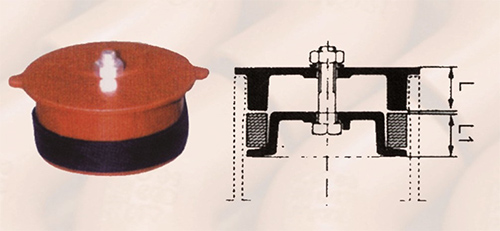

Expansion plug

| Nominal size DN | L | L1 | |

| 50 | 20 | 20 | |

| 70 | 28 | 27 | |

| 75 | 28 | 27 | |

| 100 | 28 | 27 | |

| 125 | 28 | 27 | |

| 150 | 28 | 27 | |

| 200 | 29 | 30 | |

88°short bend with heel opening

| Nominal size DN | X1 | X2 | L | |

| 100 | 50 | 112 | 115 | 202 |

| 100 | 50 | 110 | 110 | 215 |

88°short bend with vent

| Nominal size DN | X | X1 | |

| 100 | 50 | 110 | 95 |

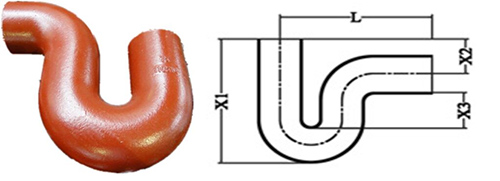

P trap

| Nominal Size DN | L | X1 | X2 | X3 | |

| 50 | 180 | 200 | 60 | 75 | |

| 75 | 180 | 200 | 60 | 75 | |

| 100 | 310 | 300 | 110 | 75 | |

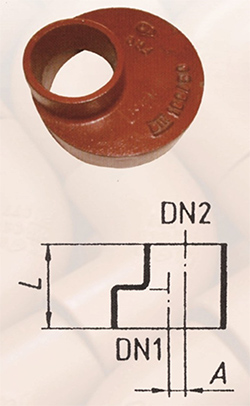

Flange adapter

| Nominal Size DN | L | X1 | X2 | X3 | |

| 50 | 180 | 200 | 60 | 75 | |

| 75 | 180 | 200 | 60 | 75 | |

| 100 | 310 | 300 | 110 | 75 | |

Product detail pictures:

Related Product Guide:

We can always satisfy our respected customers with our good quality, good price and good service due to we are more professional and more hard-working and do it in cost-effective way for China OEM En877 Cast Iron Fittings Factory Quotes – EN877 Gray Cast Iron Fittings – Jipeng, The product will supply to all over the world, such as: Kenya, Argentina, Seattle, We supply professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.